Strength Redefined. Engineered for Excellence.

Our Nickel Alloy solutions are built for superior strength, toughness, and wear resistance—perfectly suited for high-stress applications across automotive, construction, and heavy machinery industries. At TXT Group, we deliver materials that meet exacting standards, ensuring long-term performance and reliability in every project.

Our Role in the Transition

This is where we come in. We provide a pathway to enhance local producers' capabilities and facilitate their entry into international markets. Our strategic partnership with former executives from leading European Nickel Alloy manufacturers gives us a distinct advantage. By leveraging their extensive knowledge and networks, we identify and collaborate with promising local suppliers who have growth potential but require assistance in reaching global markets.

This dual approach not only improves the quality of the Nickel Alloy we offer but also ensures our partners are well-equipped to meet international standards. Together, we aim to bridge the gap between local production capabilities and global market demands, positioning ourselves as leaders in this evolving landscape.

China's Nickel Alloy Outlook

China's Nickel Alloy industry is experiencing rapid growth, yet it remains less developed compared to the established markets of Europe and the USA. This gap creates both challenges and opportunities for local producers. As demand for high-quality Nickel Alloy surges across sectors such as automotive, construction, and manufacturing, many Chinese manufacturers face a pivotal moment.

However, most often lack the experience and insights needed to navigate the complexities of export markets, including compliance with international standards, understanding customer needs, and establishing reliable distribution channels. Consequently, these producers may struggle to seize the rising global demand for Nickel Alloy , underscoring the need for strategic support and guidance.

Products

Wire Rod

Diameter: 5.5 mm — 20 mm

Finish: Pickled, Peeled, Black

Conditions: Annealed, Solution Treated, QT Treated, Aging Treatment

Round Bars

Diameter: 6 mm — 320 mm

Finish: Ground, Peeled, Polished, Cold-Drawn, Black

Conditions: Annealed, Solution Treated, QT Treated, Aging Treatment

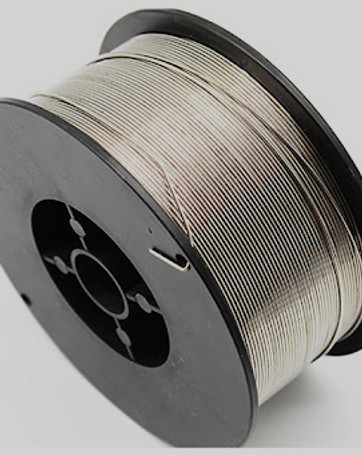

Semi-Finished Wire

Diameter: 1.5 mm - 5 mm

Finish: Full Soft & Semi-Hard, Bright & Semi Hard

Conditions: Annealed, Solution Treated, QT Treated, Aging Treatment

Coils

Finish: Mill Finish, Pickled Finish, 2B, BA, NO.1

Thickness: 0.5-6.0mm

Width: 1219mm and up

Sheets

Finish: Mill Finish, Pickled Finish, 2B, BA, NO.1

Thickness: 1.0-60mm

Width: 1000-2500mm

Plates

Finish: Mill Finish, Pickled Finish, 2B, BA, NO.1

Thickness: 1.0-60mm

Width: 1000-2500mm

Nickel Alloy

Inconel 600

UNS N0660 (Inconel 600) is a nonmagnetic nickel-chromium alloy known for corrosion resistance, high strength, workability, and performance in extreme temperatures.

Inconel 718

UNS N07718 is a strong, corrosion-resistant, age-hardenable alloy (-423° to 1300°F) with excellent weldability and fabrication.

Inconel 601

UNS N0660 (Inconel 600) is a nonmagnetic nickel-chromium alloy with corrosion resistance, high strength, good workability, and heat resistance.

Incoloy 800

UNS N08800 is a nickel alloy with excellent corrosion, heat (up to 1500°F), and stress cracking resistance plus good fabricability.

Inconel 625

UNS N06625 (Inconel 625) is a strong, corrosion-resistant nickel alloy with easy fabrication, no hardening needed.

Incoloy 800H

UNS N08810/N08811 (Incoloy 800H/HT) have better high-temp corrosion resistance and creep strength than Incoloy 800, thanks to controlled carbon and annealing.

Incoloy 825

UNS N08825 is a nickel-iron-chromium alloy with molybdenum, copper, and titanium, highly resistant to acids, stress cracking, pitting, and corrosion.

Monel 400

UNS N04400 (Monel 400) is a cold-work-hardenable nickel-copper alloy with high strength, toughness, and corrosion resistance, even in cryogenic temperatures.

Hastelloy C22

UNS N06022 (Hastelloy C22) is a versatile corrosion-resistant alloy with 22% Cr, 14% Mo, and 3% W, excelling in both oxidizing and reducing environments.

Nimonic 80A

UNS N07080 is an age-hardenable nickel-chromium alloy with titanium/aluminum, made for high-temp use up to 1500°F, produced by air-melt casting.

Hastelloy C276

UNS N10276 (Hastelloy C276) is a nickel-molybdenum-chromium alloy with excellent corrosion resistance, weldability, and ductility for harsh environments.

Alloy A286

A286 is a heat-treatable Fe-Ni-Cr superalloy with high strength, creep resistance up to 700°C, ideal for aerospace fasteners and turbine components

.png)

%201000kgs.png)

%201000kgs.png)

%201000kgs.png)