Material You Trust. Delivery You Can Count On.

Our stainless steel solutions combine corrosion resistance, durability, and precision—crafted to perform in the most demanding industries. Sourced from top-tier Chinese mills and verified through rigorous quality controls, TXT Group ensures your projects stand the test of time.

Stainless Steel Flat Products

Stainless Steel Sheets

200 | 300 | 400 series

Finishes : NO1 | 2B | 2BB | 2BA | BA | 8K Thicknesses: 0.1 - 100 MM

Width : Narrow Coils - 1500 MM

Stainless Steel Coils

200 | 300 | 400 series

Finishes : NO1 | 2B | 2BB | 2BA | BA | 8K Thicknesses : 0.1 - 100 mm

Widths : Narrow Coils - 1500 mm

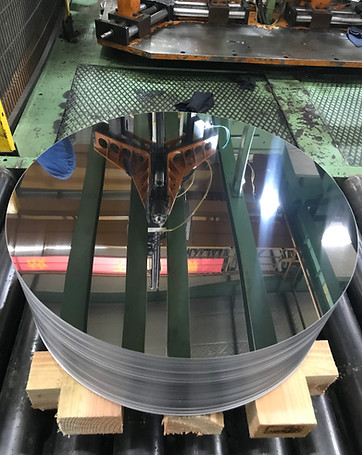

Stainless Steel Discs

200 | 300 | 400 series

Finishes : 2B | 2BB | 2BA | BA

Thicknesses : 0.3 - 1.0 mm

Diameter : 200 - 800 mm

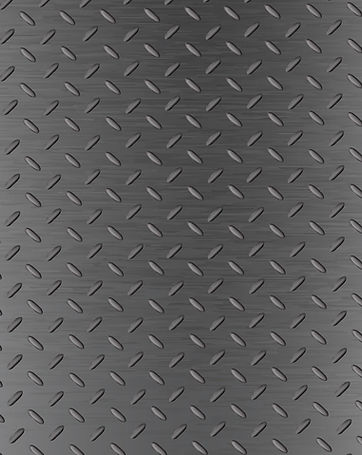

Stainless Steel Decorative Materials

Stainless Steel Decorative

200 | 300 | 400 series

For other surfaces, please contact us for more details.

Stainless Steel Colour Coils

200 | 300 | 400 series

For other surfaces, please contact us for more details.

Stainless Steel Super Mirror

200 | 300 | 400 series

For other surfaces, please contact us for more details.

Stainless Steel Long Products

Stainless Steel Bars

200 | 300 | 400 series

Finishes: Annealing | Peeling | Cold Drawn | Bright Drawn | Polish

Round Ø 1 – 410 mm | Angle Ø 20x20x30 mm – 100x100x12 mm | Flat Ø 3x5 mm – 25x150 mm | Hexagon Ø A/F5 – 14x14 mm | Square Ø 4x4 – 12x12 mm

Stainless Steel Welded Tubes

A554, A249, A269/270 Standards

Finishes: MF | Brushed | 180G | 240G | 600G Round Ø 8 – 127 mm

Square Ø 10x10 – 100x100 mm

Rectangular Ø 20x10 – 120x60 mm

Stainless Steel

201

Low-nickel austenitic steel with manganese substitution. Moderate corrosion resistance, work-hardenable. Used in cookware, sinks, and decorative applications where premium corrosion resistance isn’t essential

304

The most versatile austenitic stainless steel. Excellent corrosion resistance, formability, and weldability. Standard choice for food processing, kitchen equipment, and architectural applications.

316L

Low-carbon 316 version offering improved weldability and reduced sensitisation. Critical for welded assemblies in pharmaceutical, marine, and surgical implant applications.

430

Basic ferritic stainless steel with moderate corrosion resistance. Magnetic and cost-effective for appliances, automotive trim, and decorative applications.

443

Chromium-stabilised ferritic steel with corrosion resistance approaching 304. Cost-effective alternative for roofing, kitchen equipment, and architectural applications.

301

High work-hardening austenitic grade offering exceptional strength when cold-worked. Ideal for structural components, automotive trim, and applications requiring durability and corrosion resistance.

304L

The most versatile austenitic stainless steel. Excellent corrosion resistance, formability, and weldability. Standard choice for food processing, kitchen equipment, and architectural applications

409L

Economical titanium-stabilised ferritic grade with good heat resistance. Primary application in automotive exhaust systems and industrial heat exchangers.

439

Titanium-stabilised ferritic upgrade to 430. Improved corrosion resistance and weldability for automotive exhaust components and dishwasher interiors.

446

High-chromium ferritic grade with superior oxidation resistance. Essential for furnace components, heat treatment fixtures, and high-temperature industrial applications.

303

Free-machining austenitic grade with added sulphur. Sacrifices some corrosion resistance for superior machinability. Commonly used for precision shafts, nuts, and automatic screw machine parts.

316

Molybdenum-enhanced austenitic grade with superior chloride resistance. Essential for marine applications, chemical processing equipment, and medical devices requiring maximum corrosion resistance.

410S

Economical titanium-stabilised ferritic grade with good heat resistance. Primary application in automotive exhaust systems and industrial heat exchangers.

441

Niobium-stabilised ferritic grade with excellent hightemperature properties. Used in exhaust systems and thermal processing equipment requiring oxidation resistance.

.png)